THE CLIENT

Hexagon designs and manufactures software and hardware for surveying and machine control applications. Software using lasers and GPS now handles most of the positioning of the equipment, whereas before, it was done manually by sight. This software greatly improves the speed and accuracy of the equipment. However, defects in the software can direct the equipment to do dangerous maneuvers potentially risking human life.

BUSINESS CHALLENGES

Lowering the rate of defects that go into production by improving the testing process

Contemporary heavy machinery used in construction has advanced control systems. Software errors in these systems could lead not only to delays and dangerous situations, but also significant financial loss due to the capital-intensive nature of the machinery involved.

The client was looking for a way to optimize their testing processes with the objective to lower the amount and severity of defects that were found in production.

The ultimate goal was to provide their customers with more reliable and safer machinery while maximizing return on investment.

SOLUTION: What it Means to Partner with XBOSoft

Partnering with XBOSoft enabled Hexagon to benefit from XBOSoft’s industry experience and QA consulting expertise.

XBOSoft worked with Hexagon to improve their testing processes starting with a TPI® Assessment.

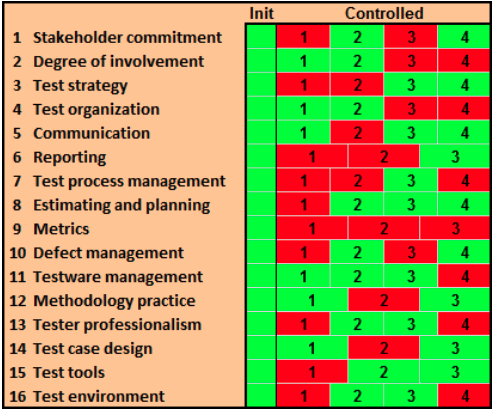

Example TIP® Maturity Matrix (sample only)

This division of Hexagon did not pass all of their checkpoints, indicating that their software development and testing processes could be improved significantly. The Maturity Matrix revealed at a glance those areas which needed to be improved and XBOSoft provided a detailed action plan for what needed to be done.

Risk Analysis

A risk analysis is critical so that everyone concentrates on what is most important first. Since it is impossible to test everything, testers can easily miss something that could cause serious problems because they end up testing unimportant things first and run out of time for more important things. A risk analysis was previously done but not in a structured repeatable way and very dependent on the specific skill set of the members conducting the analysis. XBOSoft implemented a manageable controllable risk analysis to be executed prior to each testing round that helped QA prioritize their testing resulting in fewer high severity defects in production.

Metrics

It is important to know the current situation in order to improve. Reports and metrics were generated after each round of testing but the metrics lacked standardization which made them difficult for management to use and make actionable decisions. And the metrics collected were not always the most effective looking at quality from both an end-user perspective and the most efficient internal resource allocation. To address this issue, XBOSoft developed a comprehensive set of metrics and an effective reporting format was created and implemented.

Test Strategy and Test Set-Up

Entrance and Exit Criteria were defined for each testing level which gave the testing process a consistency previously lacking. Test ware was brought under configuration management so that the Product Manager, the Software Developers, and the QA Testers were using the same documents. So, when changes were made, everyone was on the same page.

The Results

The client found and prioritized those areas for improvement in their testing process that would have the most impact on their product quality. Together with XBOSoft a plan was created and implemented to improve upon those areas resulting in creating more reliable and safer machinery.

XBOSoft’s Advantages

Working with and advising the world’s best run software teams XBOSoft knows how to set up and maintain Software Quality Processes tailored to support you in reaching your quality objectives.